Tires and Timing Belts

Tire Story: In September 2004, I went tire shopping for the Jaguar. Four years ago, I bought a set of Pirellis for $472. I called the same tire folks and they now wanted $640. Ouch. Time to Dial For Dollars. After three phone calls, I found a national chain that quoted $499. Sold.

This got me wondering if the price bump was a Euro-to-Dollar thing. I didn't know if Pirellis are made in the U.S. or only in Italy. Ten years ago, I would have shrugged the question off as a mystery. Today ... Google to the rescue. I found that Pirelli has a new 426,000 square foot manufacturing plant in Rome ... Georgia. It is claimed to be the most automated tire facility in the world, using Pirelli's revolutionary MIRS (Modular Integrated Robotized System) technology. This patented process uses robots, working at a high rate of speed, to complete the entire production cycle from compounding to finished product - without interruption, without intermediates handling and storage phases and without wasted energy. A tire can be produced every three minutes.

MIRS builds each tire around an appropriately shaped aluminum drum. Raw rubber is heated and extruded on to the drum, followed by successive layers of steel wires and strips as the tire takes shape. After curing, the drum ingeniously collapses, leaving a finished tire - ready for use. The system is flexible; change the shape of the drum and you change the tire that emerges. Properly programmed, MIRS can build car, motorcycle, truck and tractor tires.

My first engineering job was in a filthy, carbon black-laced, inefficient Uniroyal factory almost 40 years ago. Rubber manufacturing has come a long way since then. (posted 9/12/04, permalink)

Plastic Tires? Amerityre, a Nevada firm, is experimenting with making tires out of polyurethane. Prototypes have now passed some basic federal safety standards. News articles claim that "some questions remain, including the tire's ability to hold traction on wet roads and resist flat-spotting during a sudden stop."

In the 1960s, Uniroyal experimented with urethane tires. They had zero traction in the rain and, if they picked up the slightest amount of road oil, they would slip and spin until they burned up. I don't expect to see urethane tires on the road anytime soon. (posted 6/16/04, permalink)

Tires, Like Mayonnaise, Go Bad: I never knew this but old tires, even if they're stored away from sunlight, deteriorate to the point where they're dangerous. Even seven year old spare tires can suffer tread separation once they're put on the car and driven. Maybe this is another reason to get rid of the spare tire completely. Or dunk it in a vat of ArmorAll.

The UK Tyre Industry Council warned that motorists should replace tires that were "more than 10 years old, regardless of wear. The council said tire components dry with age and can separate. Anti-aging chemicals in tires are active only when a tire is in use ... spare tires, tires in storage or on a shelf, or tires that spend a long time on a trailer or a recreational vehicle run the risk of premature aging." (posted 11/9/04, permalink)

Timing Belts: Recently, I was inspecting a new Honda CR-V and was unable to hear the engine at idle - even when standing at the front of the car. Only when the hood was opened could I detect faint whirring sounds. I have rarely experienced such a quiet motor.

The moron car salesman claimed that it was due to the chain-driven overhead camshaft. This is utter baloney because chains are inherently more noisy than timing belts. Honda switched to chains because they last longer than timing belts - a sad commentary on the state of today's rubber timing belt.

My first post-college job was with Uniroyal's Timing Belt Division in Philadelphia. Uniroyal held all of the patents on the timing belt; made their belts from the finest rubber (prime-grade neoprene), fabric (neoprene impregnated, high-denier nylon) and tensile cord (high-strength, braided, coated fiberglass - precision-wound and preloaded for tension on a mandrel) and charged whatever-the-hell they wanted.

Those well-made belts could go over one-million miles without breaking; in fact, the pulleys failed before the belt did.

The first production automobile to use a timing belt in place of a chain to drive an overhead camshaft was the German-made 1962 Glas Frua coupe with a four-cylinder, 1.2-liter engine. The first American car to use a timing belt was the 1966 Pontiac Tempest on their overhead-cam, 230 cubic-inch, six-cylinder engine. (At Uniroyal, we had a Tempest Sprint company car with the factory four-speed floorshift and four-barrel carb; I drove it about 150 miles and was very impressed. 0-60 times were in the 8-9 second range - amazing for a little GM six-banger.)

General Motors paid $1.76 for each timing belt - this was at a time when they were paying less than 20¢ for a fan belt.

Now that the patents have expired, the Uniroyal plant has closed, everybody makes timing belts and the automobile companies demand a supply of cheapie, price-is-everything, quality-be-damned belts and that's exactly what they get - a piece of black, rubber-toothed crap. And that is why timing belts must now be replaced at 60,000 mile intervals, lest they break and destroy the innards of the engine.

And now you know the rest of the story ... (with apologies to Paul Harvey). Good Day! (posted 5/19/04, permalink)

Beetle Skins: For many years, OEM tires for pre-1970 air-cooled VW Beetles were 5:60 x 15 in size. The tires were less balloon-y than most non-radials and featured a relatively wide cross section for the period.

My red '63 Beetle came from the factory with Fulda Diadem tires. Great tires, very grippy - originally made in the town of Fulda, not too far from Frankfurt, Germany. But replacements were not sold in the U.S. My red '63 Beetle came from the factory with Fulda Diadem tires. Great tires, very grippy - originally made in the town of Fulda, not too far from Frankfurt, Germany. But replacements were not sold in the U.S.

When the Fuldas wore out, I replaced them with Seiberling tires which had a wrap-around tread and were pretty good, as well. In those days, Seiberling was an independent tiremaker located in Barberton, Ohio.

Today, they're just another Bridgestone/Firestone brand along with Dayton Tires - made in Firestone factories. And I've heard that the Seiberling brand has gone dormant.

Fulda Diadems are still manufactured in Germany (some in replacement sizes for old cars) although they are only available in Europe. Other Fulda tire models are sold in the U.S. and Canada although they're not easy to find. A 'cult' brand over here.

I never had Michelins nor Continentals on any of my Beetles. I can't remember the brands I used but, to save money, I once become a 'tire dealer' for a wholesaler in Camden, NJ and bought replacement tires and studded snow tires for my Volkswagens at extremely low prices.

Even though I was a 'dealer,' I was my only customer. I always got 30,000-plus miles from tires on my Beetles.

Volkswagens were frugal on tires and in almost every other respect, too. (posted 11/10/10, permalink)

Tire Tales: I've read a lot of online commentary praising Michelin tires. I've not have good luck with them. My Nissan 300ZX, both of my Lincolns and my wife's Toyota Avalon came with Michelins as original equipment. Tire Tales: I've read a lot of online commentary praising Michelin tires. I've not have good luck with them. My Nissan 300ZX, both of my Lincolns and my wife's Toyota Avalon came with Michelins as original equipment.

I didn't think much of the tires - they rode hard, wore fast and the M+S all-weathers were lousy in snow. And unexceptional in the rain.

The Michelins were replaced with either Pirellis or Toyos. I've had particularly good experiences with Pirelli tires.

A friend of mine wrote, "I stopped buying Michelin after my two Michelin All-Terrain WXR truck tires 'chunked' on the beltway at 55 mph. I complained to the company and they cut me short by telling me their truck tires aren't guaranteed because of severe service. Hell, I don't boondock, don't go off road and always check my pressures frequently.

After arguing with the Buffalo office, where the truck tires are made, and being referred to the NYC office where the executives work, they sent me a $50 discount coupon on my next set of tires. I told them to shove it, and bought Kuhmos. Better guarantee, wear very well, and used less balance weights than the Michelins."

Your experience may differ. More about tires here. (posted 3/18/11, permalink)

I'll Never Buy Tires From Costco Again: Last week, I drove to Costco and purchased a new set of Bridgestone tires to replace the originals on my Lexus. When I picked up my car, I noticed that the very nice polished aluminum valve caps had been replaced by cheap bright green plastic ones. I'll Never Buy Tires From Costco Again: Last week, I drove to Costco and purchased a new set of Bridgestone tires to replace the originals on my Lexus. When I picked up my car, I noticed that the very nice polished aluminum valve caps had been replaced by cheap bright green plastic ones.

I went back and asked, "Where are my valve caps?" I received the sheepish reply, "Ummmm... we didn't know you wanted them." Yeah, right. I'm sure that they were destined for a place of honor on an employee's Chevy low-rider. My valves were quickly returned to me after I raised hell.

All of the tire pressures were waaaaay off. And it took me over a half-hour just to clean rubbery gunk off my wheels with Goo-Gone cleaner. This is an example of disgraceful service and treatment. Costco may be OK for toilet paper but avoid the tire department.

On Thursday (a surprisingly sunny day), we got new tires for my wife's Toyota Avalon at Les Schwab Tires in Battle Ground. A very good experience - fast, polite service, attention to detail, pointing out the need to correct front toe-in (we had them perform an alignment to correct the problem) and new clean tires with no gunk on the tries or rims. Furthermore, the Avalon's chrome wheels had been cleaned by Schwab's tire crew.

After we dropped off her Toyota, we drove in my Lexus to have a delightful lunch at the Hockinson Cafe. I had the pot roast special; it was awesome. One problem: I spilled a little gravy on my Pennsylvania Railroad sweatshirt - creating a gravy train! I cleaned it thoroughly when we arrived back home. (posted 10/25/12, permalink)

How I Learned About Timing Belts: My introduction to timing belts began with a senior year Creative Engineering project at Villanova University. The specific project was to develop a stair-climbing wheelchair. How I Learned About Timing Belts: My introduction to timing belts began with a senior year Creative Engineering project at Villanova University. The specific project was to develop a stair-climbing wheelchair.

This was a continuing project on which several student groups had been assigned in prior years. The other student assignments had never gotten beyond the drawing board stage.

My good friend, Mike Stevenson (1943-92), and I partnered on this assigned project. Both of us were Mechanical Engineering majors. We came up with a new user-powered design, where the wheel of the chair transmitted power through a worm drive so the chair wouldn't reverse and run down the stairs if the user let go of the wheel (worm drives provide one-way power transmission). Our design left the tracks in the 'up' position for normal chair operation; they would pivot down below the chair's wheels for stair-climbing duties.

Our professor, George H. Auth, looked over our new design and said, "Looks good. Now, build it." But we had no money and the school offered no funding, so he encouraged us to go out and "beg" for components.

Mike and I actually drove to Ohio in a winter snowstorm (in his '62 Ford Galaxie convertible) to visit the chief engineer at American Wheelchair Co. He thought the stair-climbing idea was "a little nuts" but donated a wheelchair to the cause anyway. What a trip. It was so cold that the door locks on the car froze. I remember trying to hold the passenger door closed while Mike drove like a maniac to be on time for our appointment at American Wheelchair.

Our design called for a tracked belt drive. After some research, we decided to use a commercially-available timing belt turned inside out so that the teeth faced outward and functioned like a tank tread. Our design used three flat-surfaced pulleys per side plus one toothed drive pulley hooked to the worm gear ... (more >>>)

Replacing Air: Although others had patented it previously, the first practical pneumatic tire was produced in 1888 by John Dunlop of Belfast Ireland. It was a hollow vulcanized rubber tube filled with air. Soon afterward, tires were constructed of rubber reinforced with cord and used a rubber inner tube to help prevent leaks. Replacing Air: Although others had patented it previously, the first practical pneumatic tire was produced in 1888 by John Dunlop of Belfast Ireland. It was a hollow vulcanized rubber tube filled with air. Soon afterward, tires were constructed of rubber reinforced with cord and used a rubber inner tube to help prevent leaks.

Even in the 1920s, flat tires were a common occurrance because of rough roads and the fact that early cord-ply constructed tires were delicate and prone to punctures as were inner tubes. Flat tires were time consuming and, for business vehicles such as delivery trucks, time-wasting. If only there were a substitute for pressurized air.

Bettern-Air, the invention of a German chemist, was a vegetable compound which looked like rubber but was far more resilient. It was manufactured in 24-inch long logs, which are placed in tire casings under pressure. Bettern-Air minimized the number of flats and its spongy nature provided a smooth ride - like a pneumatic tire.

In this 1915 photo ... (more >>>)

Sustainable Tires Of The Future: Michelin claims it will offer 100% sustainability in its tires by 2050. "As of 2020, 30% of the components that are used to produce a Michelin Group tire are made from "natural, recycled or otherwise sustainable raw materials." Which means 70% aren't."

The company hopes to use bio-sourced butadiene, a material used to produce synthetic rubber. Biomass from wood, rice husks, leaves, corn stalks and other plant waste can be used.

It also wants to use recycled styrene, a monomer that can be in the production of synthetic rubber. The material is obtained from things such as packaging waste. Most tires use styrene-butadiene rubber (SBR).

A supplier proposes to use enzymes to deconstruct PET plastic waste (old soda/water bottles) into monomers, including polyester yarn that can be used in tire manufacturing. And, finally, Michelin wants to expand its efforts in reclaiming old tires. (posted 4/12/21, permalink)

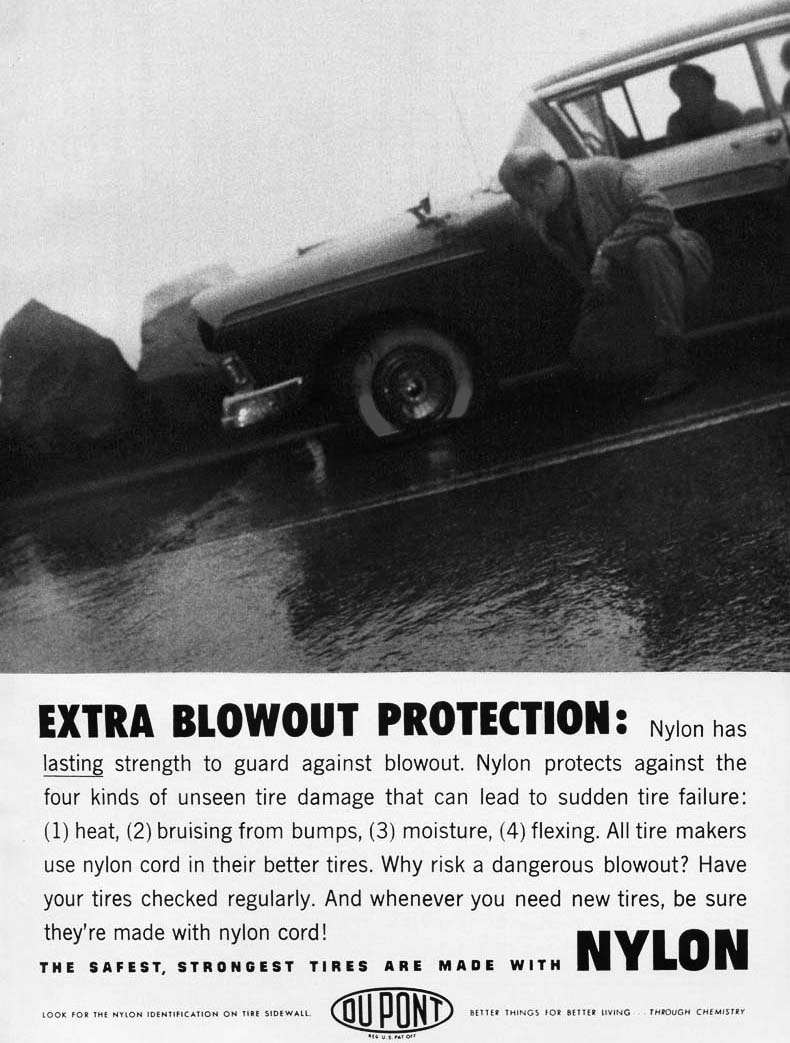

The Importance Of Nylon Cord In Tires: The first practical pneumatic tire was made in 1888 by Scots-born John Boyd Dunlop in Belfast, Ireland. Eventually, a company was formed to manufacture Dunlop-brand tires. Most tires used cotton for cord and fabric applications. In the mid-1930s, rayon began to be substituted for cotton because it had higher tensile strength and improved elastic modulus.

Nylon - a synthetic thermoplastic - was developed by DuPont in the mid-1930s. Nylon was first used commercially in a nylon-bristled toothbrush in 1938 followed more famously in women's stockings or "nylons" which were shown at the 1939 New York World's Fair and first sold commercially in 1940. During World War II, almost all nylon production was diverted to the military for use in parachutes and parachute cord.

Because of nylon's improved chemical resistance, it was difficult to bond to rubber. Herman E. Schroeder, who joined DuPont in 1938, developed the first practical adhesive for bonding rubber to nylon for B29 bomber tires. He served as DuPont's Director of Research and Development for synthetic rubbers and plastics from 1963-1980.

Nylon cord in tires was used by the military during World War II. In 1947, the first nylon tires were developed for the consumer market. Nylon is stronger than rayon, is also more resistant to heat and remains stronger at elevated temperatures. Nylon absorbs less water than rayon as well. In the 1950s, nylon was the choice for premium tires.

Later, polyester cord and steel belting replaced nylon as radial tires became more prevalent. (posted 8/12/21, permalink)

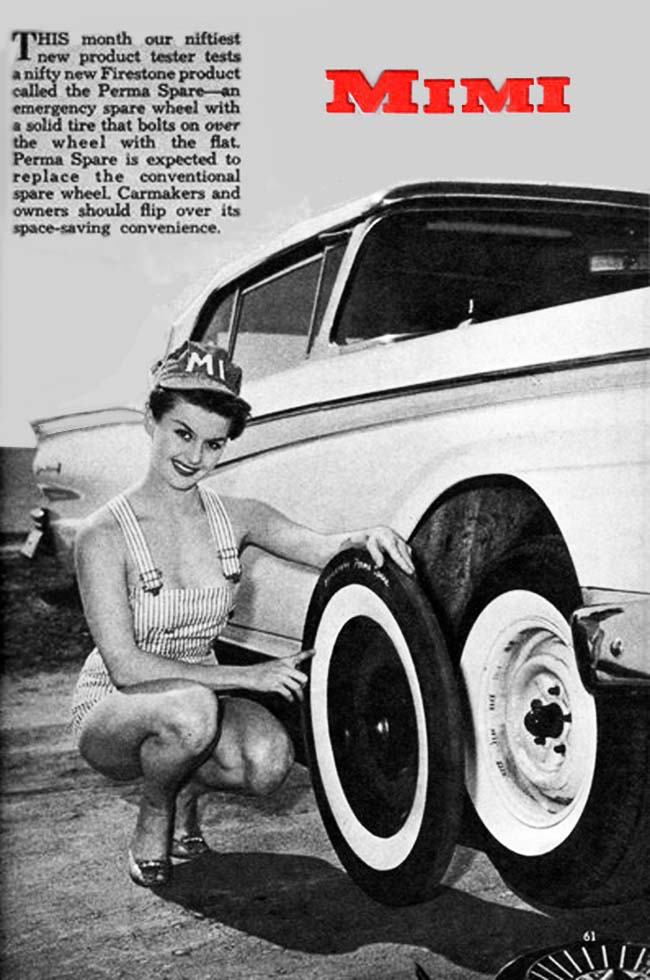

Early Space-Saver Spare: Anyone remember Mimi from Mechanix Illustrated?

Here she demonstrates a prototype of a Firestone Perma Spare - a steel wheel with a thin solid tire that bolts over the wheel with the flat. (posted 9/21/21, permalink)

The Quest For New Tires: It was time for our Avalon to get new tires. We bought our last set in 2012 and, while there was still some tread on them, they were worn enough that I was concerned about the coming winter's worth of Northwest rain and slippery roads. I had read that new tires - like almost everything else - are getting scarce due to supply chain issues. The Quest For New Tires: It was time for our Avalon to get new tires. We bought our last set in 2012 and, while there was still some tread on them, they were worn enough that I was concerned about the coming winter's worth of Northwest rain and slippery roads. I had read that new tires - like almost everything else - are getting scarce due to supply chain issues.

We had been purchasing Toyo Tourevos, ever since we replaced the original equipment Michelins (which I didn't like), from the Les Schwab Tire Center in Battle Ground. I called about buying new tires and found out that Schwab no longer carries Toyos and that the best they could do was Bridgestone Dueler H/L 400s, which I found out later was a truck/SUV tire, shipped from Nevada to arrive in three weeks or so. Celine told me that there was only a relatively short three-year warranty and no mileage warranty. She seemed confused by the tire size, stating that this was a very unusual size of tire. Huh? Every Les Schwab rep I've ever spoken with before had great product knowledge The price she quoted was 250% higher than we had paid for the Toyos.

A couple of days later, we visited Dick's Point S in Battle Ground. Scott quoted three different brands of tires. Two (Nokian and Kelly) were made in the U.S.; the third brand - a name I didn't recognize - was made in China. We chose Nokian One tires for the Avalon. Dick's had them in stock and installed and balanced them in less than two hours. Our total cost, including mounting and balancing was less than half the price quoted by Les Schwab.

We've been loyal customers of Les Schwab for over 40 years. But, in 2020, the family-owned company was sold to a hedge fund and I guess things have changed. We'll think twice before returning to Schwab for our future tire and battery needs.

I wasn't familiar with Nokian tires, but did a bit of research and found that they have quite a history. The company's roots go back all the way to 1898, when Suomen Gummitehdas Oy (aka: Finnish Rubber Works) was founded.

In 2021, Finland-based tiremaker Nokian rolled out a new all-season passenger-car tire called the One that's specifically designed for North America. The tire has a novel feature of pothole protection using aramid fibers (a material used in bulletproof vests) to reinforce the sidewall. Nokian will replace the tire if damaged beyond repair due to potholes. And, it has a 60,000 mile warranty.

The tires are manufactured at Nokian's Dayton, Tennessee factory which opened in 2017 and are reputed to be quiet, smooth and very good on wet roads. That's exactly what we want. (posted 11/4/21, permalink)

copyright 2004-21 - Joseph M. Sherlock - All applicable rights reserved

Disclaimer

The facts presented on this website are based on my best guesses and my substantially faulty geezer memory. The opinions expressed herein are strictly those of the author and are protected by the U.S. Constitution. Probably.

Spelling, punctuation and syntax errors are cheerfully repaired when I find them; grudgingly fixed when you do.

If I have slandered any brands of automobiles, either expressly or inadvertently, they're most likely crap cars and deserve it. Automobile manufacturers should be aware that they always have the option of trying to change my mind by providing me with vehicles to test drive.

If I have slandered any people or corporation, either expressly or inadvertently, they should buy me strong drinks (and an expensive meal) and try to prove to me that they're not the jerks I've portrayed them to be. If you're buying, I'm willing to listen.

Don't be shy - try a bribe. It might help.

|